Agriculture, Manufacturing & Industry

Grow. Support. Learn.

Online Options

Agriculture - Farm & Ranch

Agriculture - Precision Ag

Automotive Technology

Construction Technology

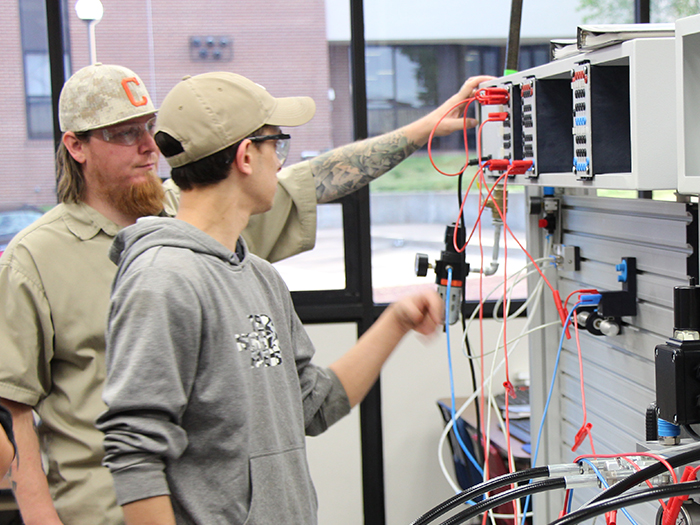

Electromechanical Maintenance

Machine & Tool Technology

Milling (Flour) Technician

Nondestructive Testing

Welding Technology

Wind Energy Technology

Not Sure? Let Us Help

Find Our Campus

Location

125 S. 2nd St.

Arkansas City, KS

Contact Info

800-593-2222

admissions@cowley.edu

Take a Tour

Want to take a closer look? Don’t have time to make the trip?

Our Virtual Tour is the next best thing.

Follow us for an in-depth look at our beautiful campuses.

More Areas of Study

Cowley College offers over 120 different programs of study that guides a student on a pathway toward earning a degree or college certificate.

Whether your future career looks like becoming a teacher, cosmetologist or politician, learn through experiences by selflessly giving your time & talents to help the community and devote yourself to your education. Our social sciences teach you how to be successful in your personal and professional life.

In two years or less, you can earn certificates for legal, business, & medical offices careers. While our social sciences teach you how to be successful in your personal and professional life. Learn through experiences by selflessly giving your time & talents to help the community and devote yourself to your education.

Learn how to provide acute care for the critically ill and injured on scene and during transport. Earn credentials for a successful career in law enforcement and corrections. Studying these programs prepare students to provide services to communities and individuals.

Enrich your knowledge and skills through diverse writing and literature courses. Contribute to the voice of the students through a newspaper published online and on paper. Perfect skills in photography, broadcasting, news reporting, and public relations.

Covers diverse fields such as forensic science, chemistry research, and medicine. Includes fascinating courses in human anatomy, microbiology, and human heredity - explore foundational skills and both mathematical & conceptual principles present in our physical universe.